About us

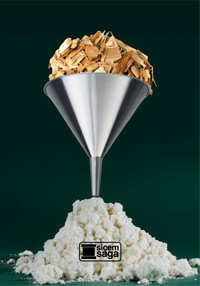

Sicem Saga has over 50 years' experience in pulp production field.

The mill is located northern Italy in the middle of the Padana flat well known for its poplar plantations. It was planned by Eng. Giorgio Gazza in 1960 with the aim of utilizing wood chips coming from the many saw mills and plywood manufacturers of the area.

A leading pulp producer in Europe, Sicem Saga has designed and developed a patented technology to optimize the inherent properties of poplar wood to produce pulp grades with brightness from 30-85, and shopper from 30-57. This technique allows Sicem Saga to adjust main mechanical properties to suit customers' individual paper products.

Today the Company is proud to have a vast client portfolio around the globe. Sicem Saga has stable and long-term cooperation with customers in EU, and is also presented in Africa and Middle East. In 2010, SS entered China's market, and has developed a strong group of customers producing cultural paper, packaging for consumer goods and food, tissues, wallpaper, etc. SS also provides pulp mix and use analysis for certain customs to help customers to achieve the right balance between quality and cost. It's tested and proved by customers that SS CMP is excellent for high speed PMs and is of consistent quality.

With a production capacity of 100.000 t/y, Sicem Saga has its strength in the flexibility of the equipment, which enables us to produce a wide range of high yield pulps, whose quality is suitable for many different applications. Our Customers range from the production of woodfree and wood-containing white papers (coated and uncoated), tissue paper, high quality board, saturated base paper, etc.

Sicem Saga has focused its attention on the environment and is always at the forefront in anticipating these needs, as proven by the environmental ISO 14001 and forest FSC certifications held by the Company for many years. The high process yield, the use of recovery and fast growing raw material, low energy and water consumption (compared with the BAT, Best Available Technology), all help significantly to reduce environmental impact.

|